In February of 2020, ASTM D8267 (official test method for the analysis of aromatics in Jet Fuel) was concurrently balloted to the ASTM committees (D02.J001 sub and main D02) on jet fuel for inclusion inot the ASTM D1655 specification. This ballot closed on March 26th, 2020.

There were no challenges to the technical merits of the D8267 aromatic measurement nor the 25.0% vol max aromatic limit. While the method did receive one negative from a competitor, it was quickly withdrawn.

As a result, ASTM D8267 will now be officially included in ASTM D1655 as an official alternative method to ASTM D1319.

The scope of ASTM D8267 that was balloted and approved in D1655 is for the measurement of total aromatics up to 25.0 vol%. For comparison purposes, the D1655 jet specification aromatic limit is 25.0 vol% for ASTM D1319 and 26.5% for ASTM D6379.

The scope of ASTM D8267 covers total aromatics in Jet Fuel from 0.487 % by vol to 27.876 % by vol. The supporting data for the ballot showed equivalency with D1319 and therefore, D8267 is suitable for measuring aromatics at the specification limit of 25.0 % vol without any correlation or correction factor. The lower limit of the scope will facilitate adoption into ASTM D7566 specification for sustainable alternate jet fuels. VUV will begin the ballot process for this in 2020.

Yes. Inclusion of D8267 aromatics as an accepted method for the D3338 calculation was balloted concurrently at D02 main and D02.05. The ballot received no negatives and one comment and a revision of D3338 is expected to be published on a similar timeline to D1655.

Prior to the most recent ballot the ASTM D1655 jet fuel specification only referenced two methods — D1319 (referee) and D6739-11 (alternative). Like D8267, other methods are also being worked on. The information below is a brief overview of the current situation of each method:

ASTM D1319 (FIA)

- In late 2018, it was learned that a critical component used in the dye formulation required for D1319 was no longer available as the sole-source provider had gone out-of-business. As a result, the supplier of the dye attempted to reverse engineer the formulation, producing five lots of new dye. These lots (3000000975 through 3000000980) were ultimately banned for use in methods that measured aromatics in fuels, including Jet Fuel, because they will provide incorrect results.

- Since that time, the supplier of the dye has developed a new “prototype formula” that is purportedly “chemically equivalent” to the original D1319 dye. A ruggedness study was completed comparing the ASTM D1319 legacy dye to the prototype dye on gasoline, jet and diesel samples. The ruggedness study design included running legacy dye side by side with the prototype dye, while accomplishing an initial evaluation of dye efficacy. This may have biased results for the technicians since they knew the answers before they took the test. the conclusion of the study was the dyes were the “same but different”.

- This new dye will require an InterLaboratory Study (ILS) to evaluate it against the legacy dye. As of today, this ILS has not started. It is currently unclear what the timeline for the ILS will be.

- The D02 main ballot to revise D1319 has received three negatives which will need adjudication before prototype dye is recognized.

ASTM D6379-11 (HPLC)

- This HPLC method provides determination of mono-aromatic and di-aromatic hydrocarbon group types in aviation kerosenes, jet fuels (Jet A, Jet A-1) and petroleum distillates (50 – 300°C) using Refractive Index Detection (RID). The test method is appliable for petroleum distillates with mono-aromatic hydrocarbon content of 10-25 % m/m and di-aromatic content of 0-7 % m/m.

- This method is undergoing the ASTM ballot process for revisions and updates, as it is dated to 2011. Jet Fuel specifications limit aromatics to 25.0 volume %. D6379 reports in mass % and thus does not have a valid precision statement for volume %; although jet specifications cit D6379 as an alternate method.

ASTM D8305 (SFC)

- This test method provides determination of mono-aromatic and di-aromatic hydrocarbon group types in aviation fuel using Supercritical Fluid Chromatography (SFC) with Flame Ionization Detection (FID).

- This method is based on ASTM D5186 and is in the ballot process at the D02.J subcommittee level. If this passes, the the earliest D1655 recognition is after December 2020.

Yes. As part of the August 16th, 2019 method ballot, VUV Analytics submitted our research report that details the results of our ILS. This ILS involved running 24 samples at 10 different laboratories and was completed in April 2019.

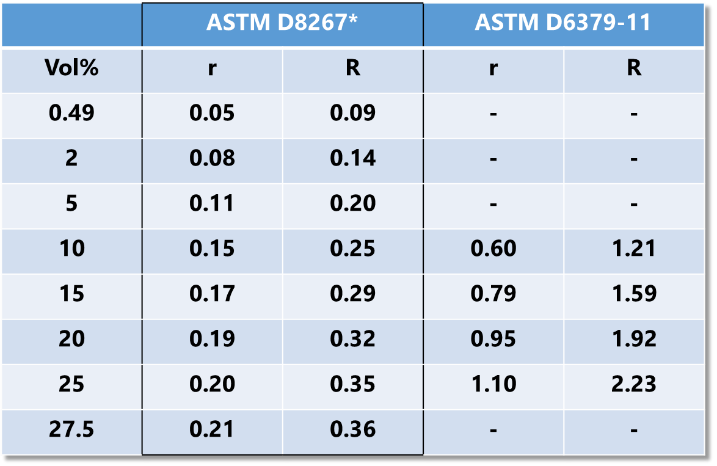

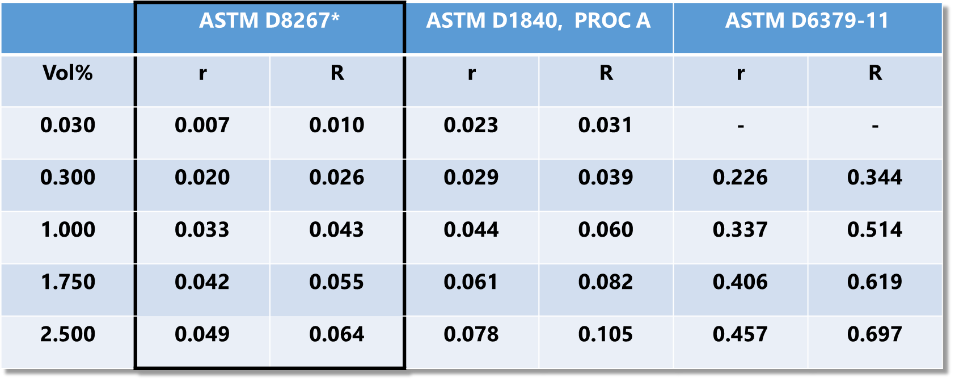

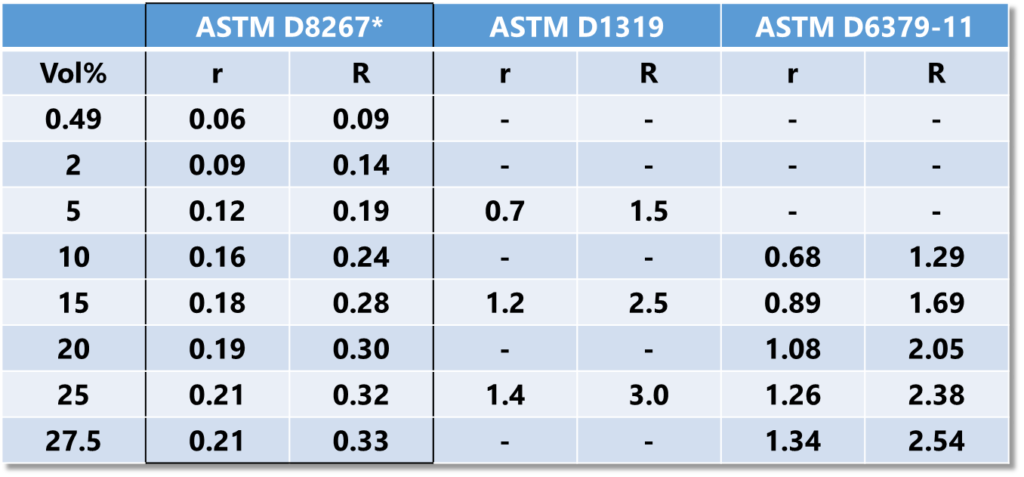

Based on the ILS data, the precision of D8267 is excellent and on average five (5) to ten (10) times better than other methods. The ILS successfully determined repeatability (r) and reproducability (R) in accordance with D6300 requirements. Please refer to table 1 for the D6300 precision analysis.

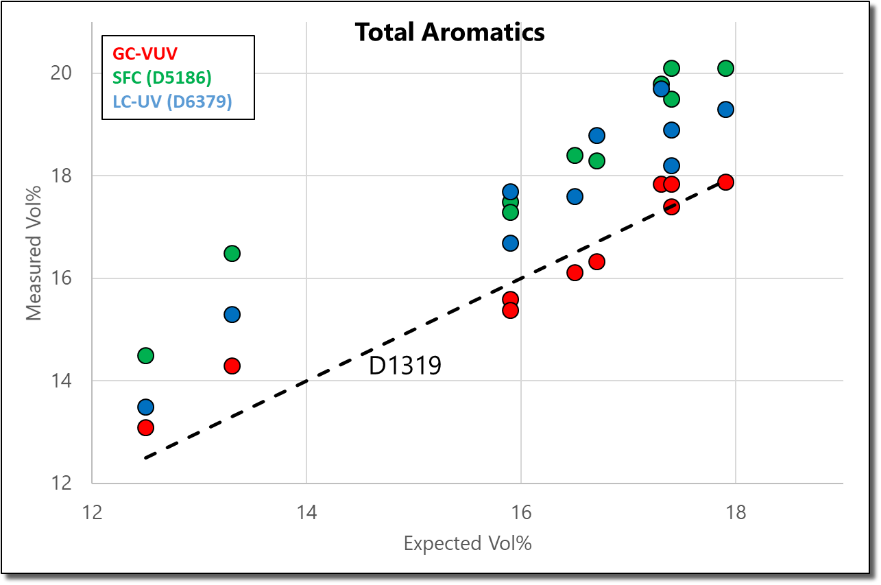

As noted, the precision of D8267 is excellent and on average five (5) to ten (10) times better than other methods that are currently used for jet fuel analysis. Figures 1 – 3 highlight the precision of ASTM D8267 compared to ASTM D1319 and ASTM D6379-11 for mono-, di-, and total aromatics.

Figure 1 – Mono-aromatic precision (5-10x better)

Figure 2 – Di-aromatic precision compared to D1319 & D6379-11 (5 – 10x better)

Figure 3 – Total aromatic precision (5 – 10x better)

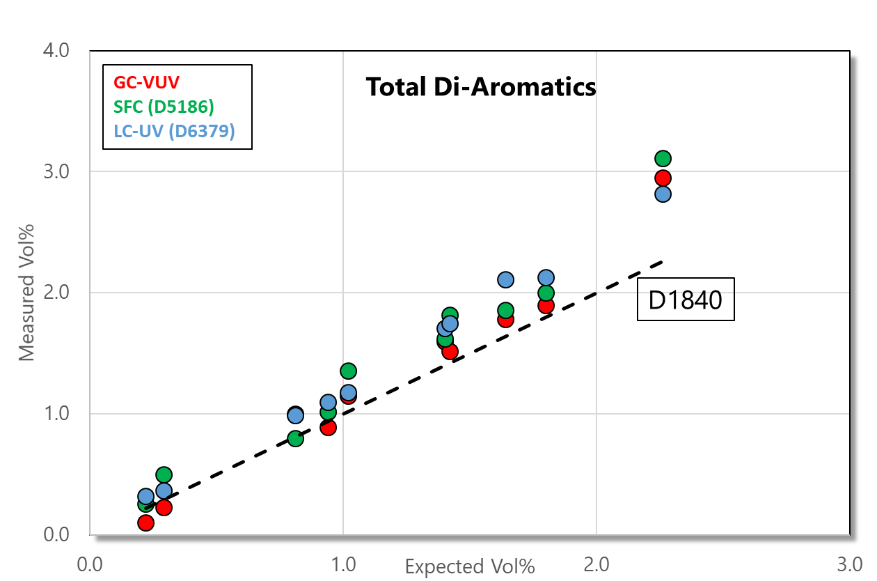

Comparison data can be seen in figures 4 and 5. This data compares ASTM D8267 with ASTM D1319, ASTM D1840, ASTM D5186. In all cases, ASTM D8267 has better performance to the other methods.

Figure 5 – Comparison of D8267 to alternatives for Di-Aromatics

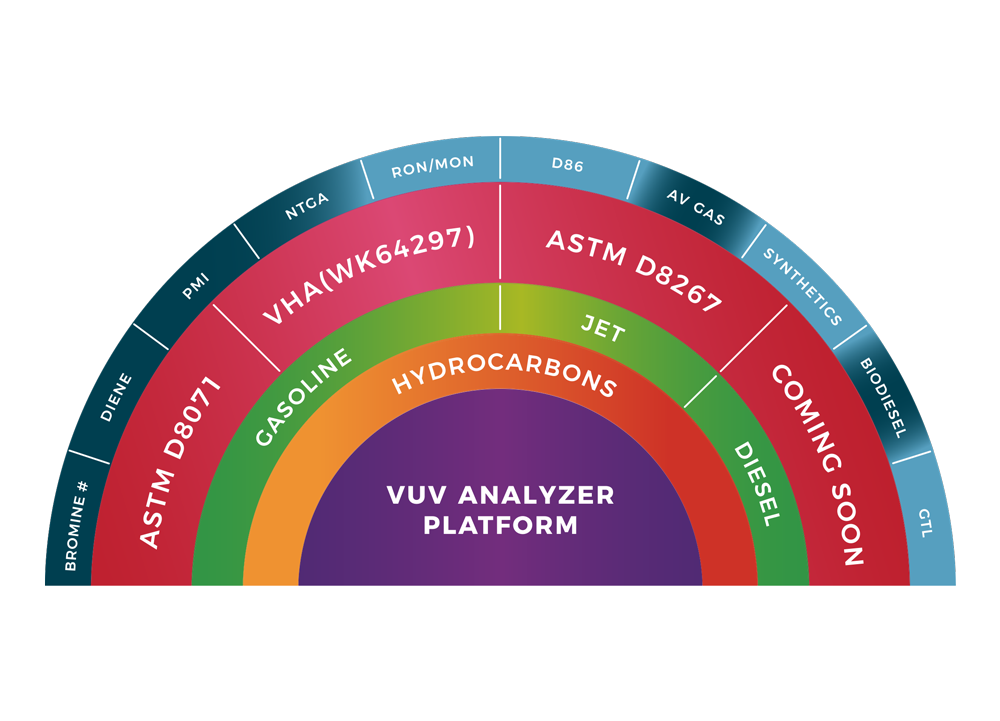

Yes. One of the biggest advantages of these methods is that they can be run on the same VUV Analyzer™ Platform with no changes in hardware or setup. This will provide a simple and cost-effective means to maximize productivity because the VUV Analyzer can be repurposed based on laboratory priorities.

Figure 6 – VUV Analyzer for Fuels. One Platform – Endless Possibilities.

ASTM D8267 has numerous advantages, including:

- Superior precision. As noted, ASTM D8267 is 5-10x times better than the alternatives.

- 14-minute analysis time.

- Easy Calibration. Automatic determination of mass and volume % with no calibration curves required.

- No sample prep. Unlike the alternatives that require extensive sample preparation and column packing D8267 requires no sample prep.

- Minimal maintenance. D8267 running on the VUV Analyzer for fuels requires minimal maintenance because it utilizes a robust single capillary split/splitless inlet on any GC. Additionally, consumable requirements are minimal as there is only a single hardware consumable (lamp) and the system has lower usage on high purity gases.

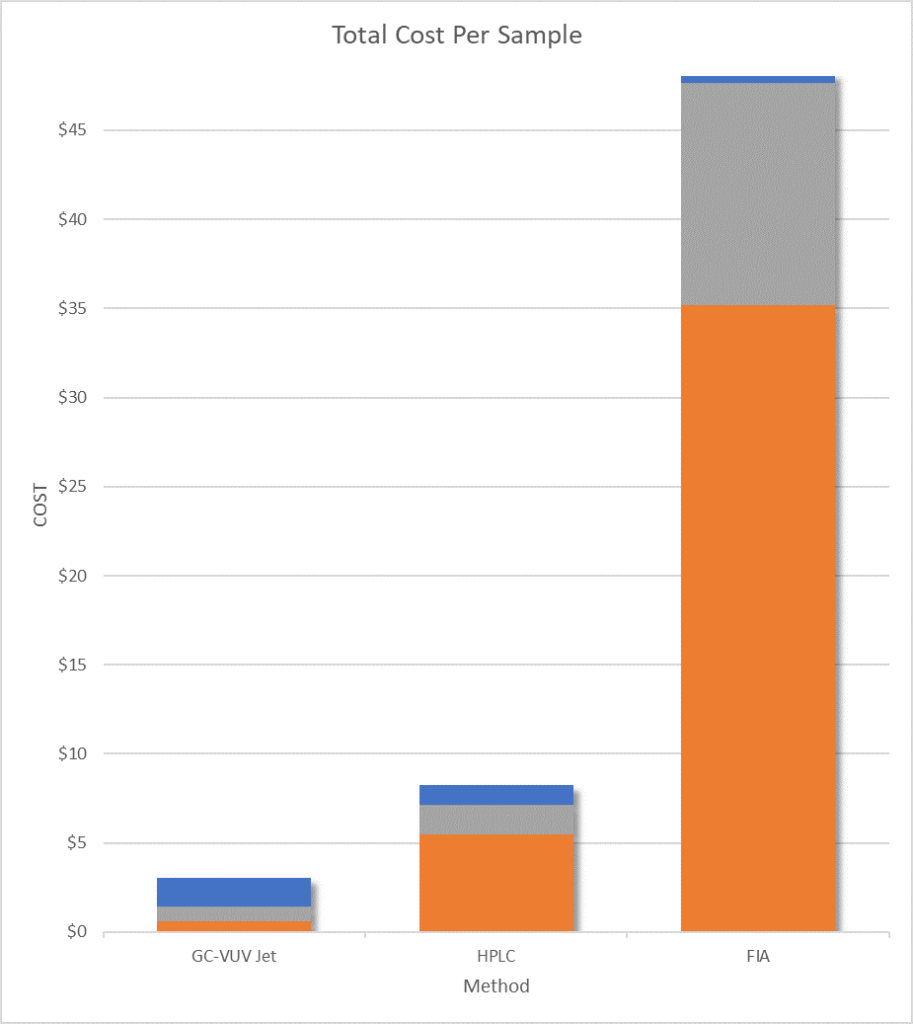

- Lower cost to operate. Running ASTM D8267 on the VUV Analyzer for fuels costs 10 – 12 times less to operate than D1319 and 5-7 time less to operate that D6379 on a per sample basis (Figure 8).

Figure 8 – Total cost to operate per sample

ASTM D8267 is easy to run and operate. If you want to be up-and-running as soon as possible it is important to consider the following:

- Instrument lead time for the VUV Analyzer™ is typically 45 day from receipt of a PO. However, as there is considerable interest in this platform, delivery expectations could increase, so it is important to take your laboratory needs into account and order as soon as possible.

- As far as inclusion in DefStan 91/091, VUV is already petitioning the British MoD. DefStan 91/091 is expected to follow the ASTM lead for method citations but the process may take until the second half of 2020 to complete.

- The application of fit for use metrics in “ASTM D8146 – 18 Standard Guide for Evaluating Test Method Capability and Fitness for Use”, when comparing aromatics in jet fuel methods, results in a clear winner – D8267. The D8267 method running on the VUV Analyzer for Fuels has the best precision, widest applicable concentration range (scope), best analytical performance value (APV) and lowest precision ratio (PR).

- The versatility and scalability of the VUV Analyzer Platform is unique. Not only can you use a single VUV Analyzer to analyze jet fuel, but you can also certify gasoline and measure aromatics in diesel fuel. At the same time the VUV Analyzer Platform can be scaled from R&D to production with excel reproducibility. This unique capability provides for a very cost-effective analysis platform.