Published Ryan Schonert on January 29, 2020

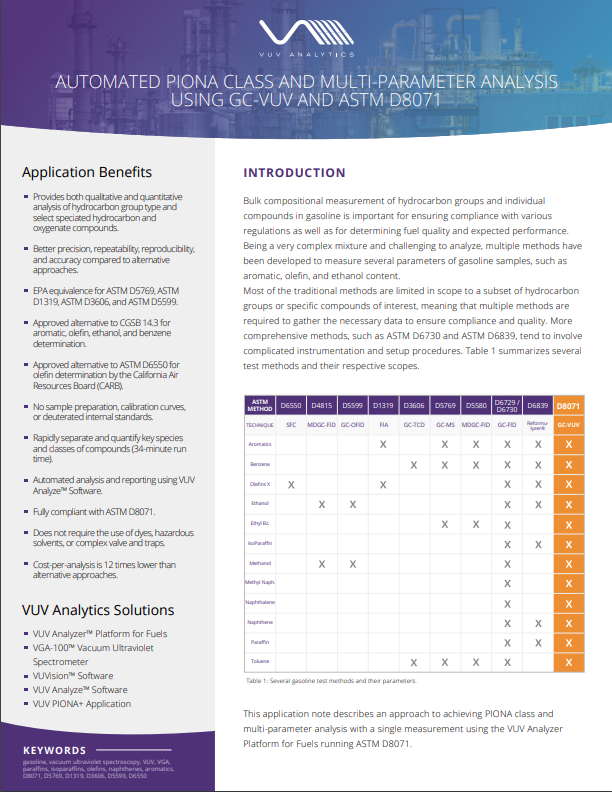

With ASTM D8071 for gasoline, ASTM D8267 for jet fuel, and a diesel method on the way, VUV has proven to be a versatile fuels analysis platform. These methods provide powerful results with spectral confirmation, and their analysis times are shorter than traditional methods. However, these methods don’t cover very light compounds in the C1-C3 range because they volatilize too quickly under normal GC injection conditions. Since small molecules have the most interesting and unique VUV spectra, we’ve been exploring ways of analyzing these samples in our lab.

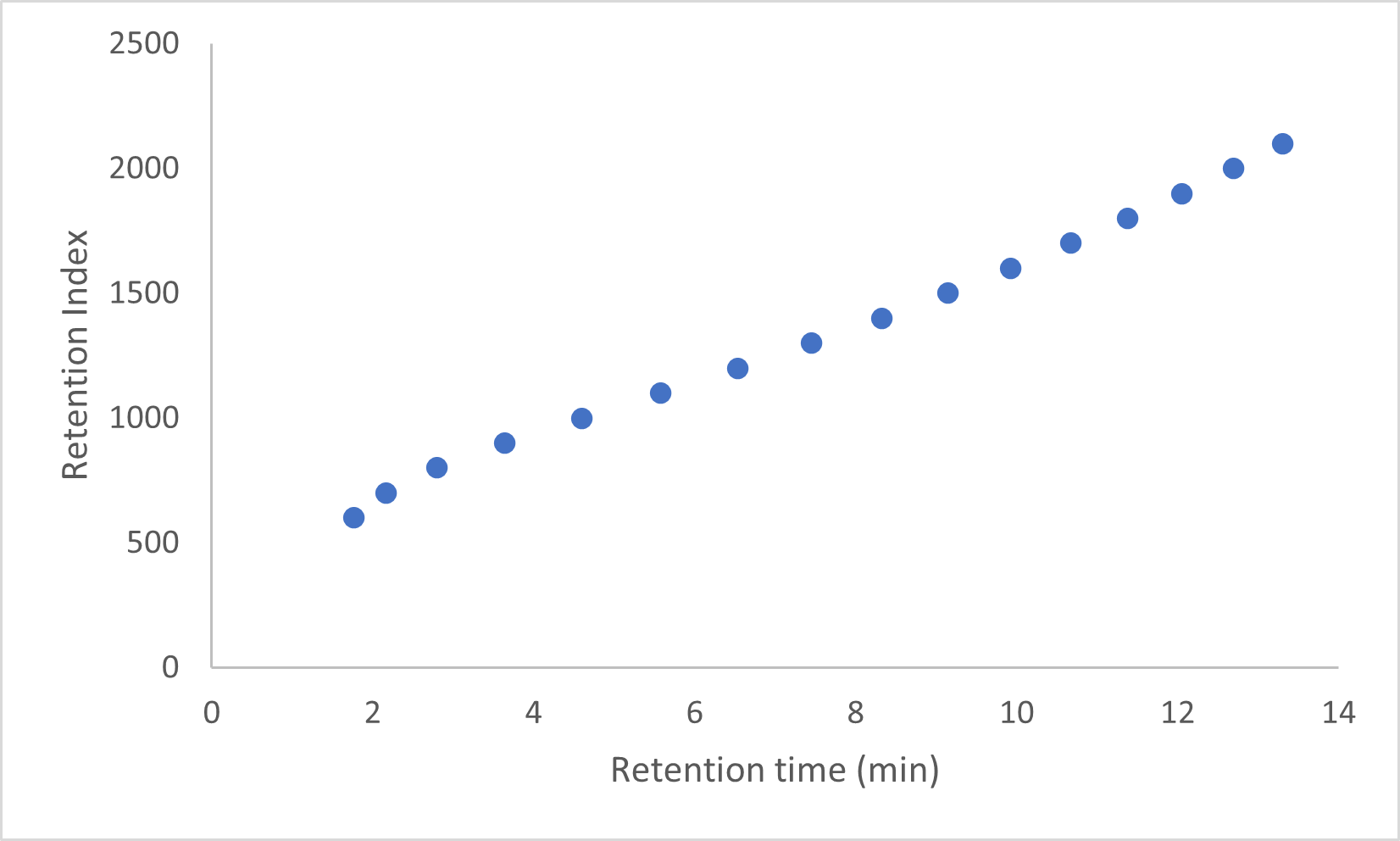

There are several options for analyzing gaseous samples on a GC, but injecting a gas into a GC often yields broad peaks which can lead to poor chromatography. Instead, it’s possible to pressurize these compounds into liquids, often called liquefied petroleum gas (LPG), and inject the liquid sample using a liquefied gas injector (LGI). Injecting the sample as a liquid provides sharp, resolved chromatographic peaks, making it easier to pick out compounds at small concentrations from much larger peaks. Even if the sample is composed of permanent gases which can’t be liquefied, the pressurized injection provided by the LGI still improves the chromatography.

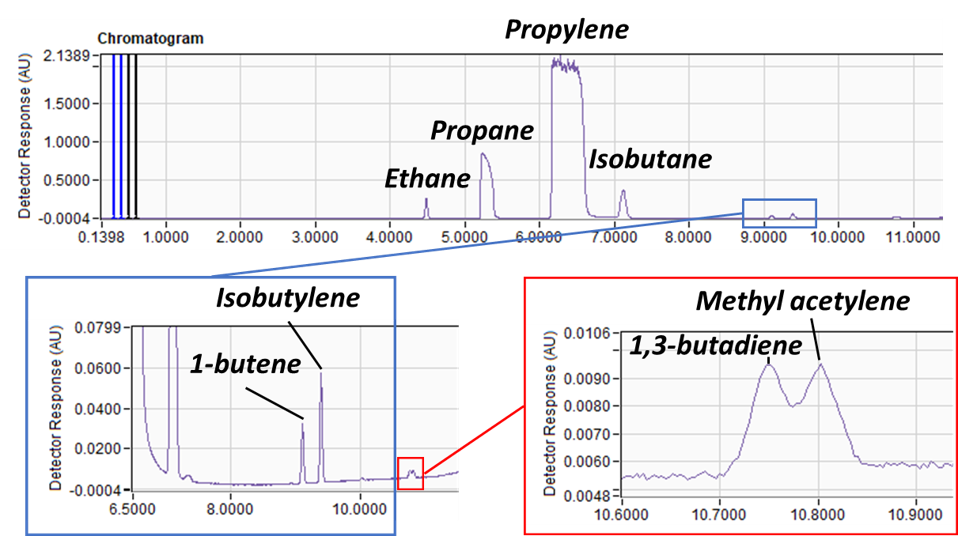

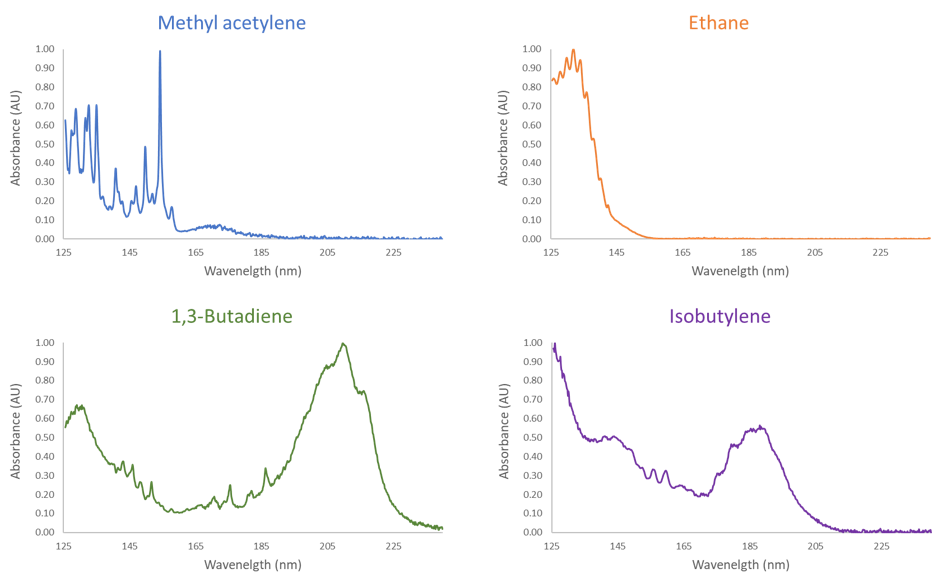

We recently set up an LGI system in our lab, and the results have been quite exciting! Figure 1 shows an analysis of a propane/propylene sample analyzed with a VGA-100. Volatile compounds which would normally be lost in a traditional GC liquid injection are clearly visible and well-separated, allowing us to take advantage of these compounds’ very distinct spectra for identification. Figure 2 shows some of the unique spectra obtained from these small molecules, which often contain sharp features that are recognizable even at trace levels.

VUV has an advantage for these samples over the traditional FID detector because like our other methods, VUV provides spectral confirmation of compound identifications. Additionally, VUV can still deconvolve coelutions that may still occur, simplifying quantitation and boosting confidence in results. Pairing an LGI system with VUV may lead us to new methods, such as a VUV-version of ASTM D2163. Be on the lookout for LGI-GC-VUV applications in the future!

Figure 1. Analysis of a propane/propylene sample. The large propane and propylene peaks are clearly visible, while smaller peaks are separated and easily identifiable. The additional separation allows us to distinguish compounds in small amounts, such as 1,3-butadiene and methyl acetylene, in a mixture containing primarily propane and propylene.

Figure 2. Spectra of compounds in the propane/propylene sample. Small molecules tend to have very distinct spectra containing sharp features that are easily recognizable and very useful for compound identification, even at small concentrations.

Ryan,

What’s the concentration of the 1,3-butadiene in your example?

After a quick check in VUV Analyze, I believe the concentration is less than 0.005 mass% – however, this sample was an older propane/propylene sample we used for qualitative purposes, so I don’t have any specifications for it. Do you have any applications in mind involving LPG samples with 1,3-butadiene?