Published James Diekmann on June 12, 2019

Detecting Methanol in Light Crude Oil with GC-VUV

By: James Diekmann

I don’t know about you, but I DON’T like the idea of directly injecting crude oil into my gas chromatograph for determination of volatile compounds like methanol. No thank you. Instead, I’d rather use a less abrasive injection technique – sampling the headspace. For this blog post, I’m interested in detecting methanol in crude oil – a compound that is highly volatile and partitions easily into the headspace from crude oil.

For those of you wondering, methanol is used in crude oil to prevent gas hydrates forming in pipelines. Unfortunately, residual methanol in crude oil can lead to costly problems in refinery operations by negatively impacting water treatment facilities.

Traditional methods like ASTM D7059 involve direct injection of crude oil into a gas chromatograph, requiring backflush capability to properly analyze methanol with a flame ionization detector. To avoid a direct injection of crude oil, static headspace – gas chromatography – vacuum ultraviolet spectroscopy (SH-GC-VUV) can be used as an alternative method. This technique simplifies the GC configuration and saves the GC inlet and column from crude oil contamination, while also providing spectral identification and quantification of methanol.

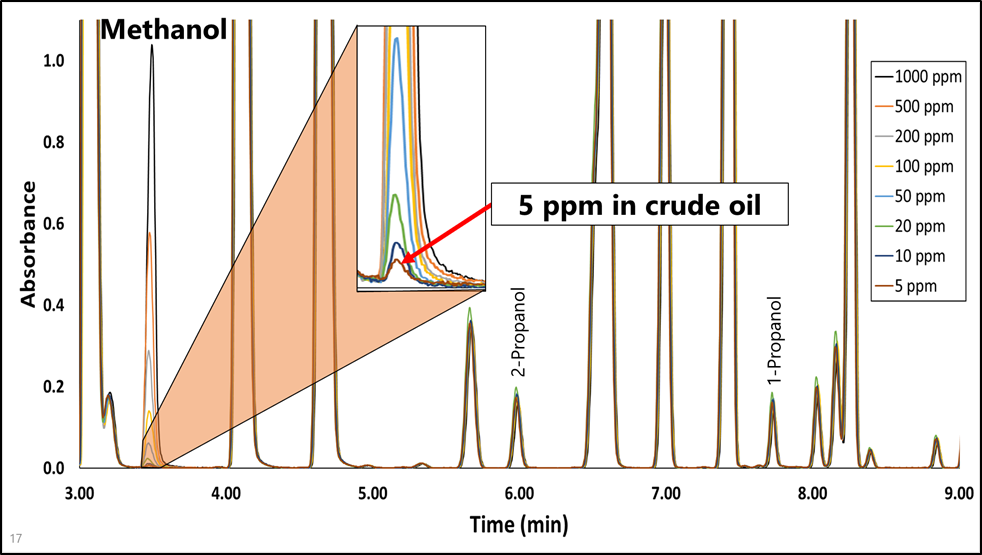

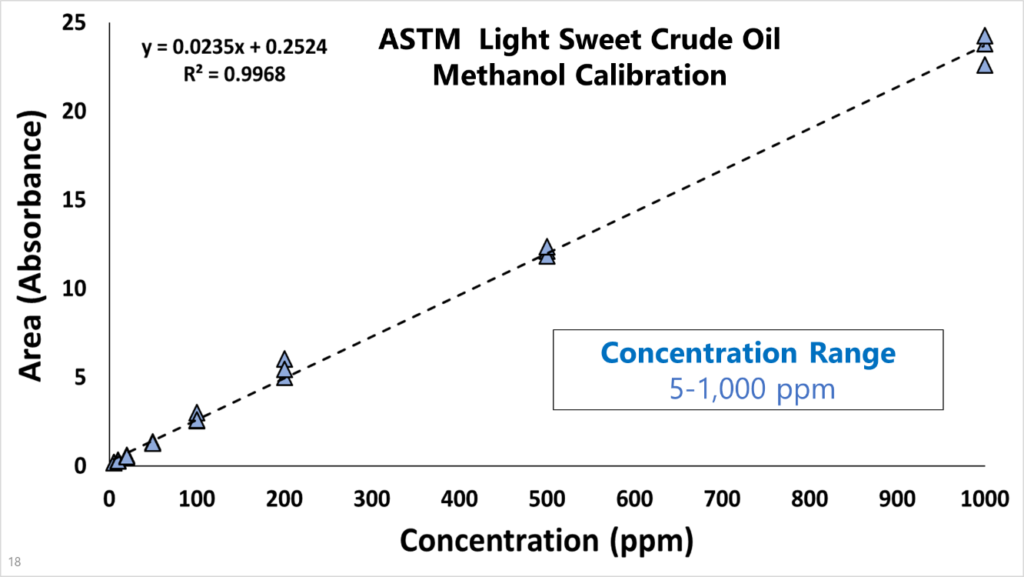

Figure 1 shows an example chromatogram of methanol in an ASTM light crude oil, using SH-GC-VUV. The methanol peak is baseline resolved, meaning it is well separated from water and other compounds. The inset plot shows that methanol can be detected down to 5 ppm, which is comparable to existing methods. SH-GC-VUV calibration curves for methanol in crude oil from 5 to 1,000 ppm showed good linearity (Figure 2).

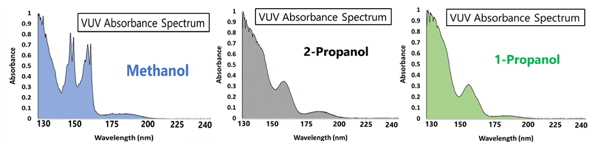

To emphasize the importance of VUV absorbance spectra, Figure 3 shows examples of methanol, 2-propanol, and 1-propanol. Even though they are all classified as alcohols, each VUV spectrum is unique, even for the two isomers.

In my opinion, if you want to avoid gunking up your GC, headspace GC-VUV is a viable alternative for analyzing volatiles in crude oil!

Figure 1. Chromatogram of crude oil spiked with various levels of methanol, and 1-propanol and 2-propanol as internal standards, all baselined resolved. All crude oil compounds elute in under 20 minutes.

Figure 2. Duplicate calibration curve, covering 5ppm to 1000 ppm. The curve is linear with an R2 greater than 0.99.

Figure 3. VUV absorbance spectra of methanol, 2-propanol and 1-propanol.

Nice application, really demonstrates the power of GCHS-VUV. Also clearly demonstrates great alcohol separation and detection.

I believe GCHS-VUV is the way forward for all residual solvent analysis especially for Pharmaceutical applications.

Thanks for the response David Green! GC-VUV is a fantastic detector for volatile analysis and couples very well with headspace.

Funny that you mention residual solvents in pharma. Although most of our blogs have revolved around petrochemical, we do have posts on residual solvents in our blog vault. For example, a blog post by Jack Cochran entitled “Residual Solvents Analysis – The Lazy Analytical Chemist” that talks about using headspace GC-VUV for residual solvents.

If you have any specific questions, feel free to shoot me an email at james.diekmann@vuvanalytics.com or leave another comment!

Thanks James for sharing. I would however like to add that unless a lab does have many applications to make full use of the VUV otherwise having a HS with VUV is something most of the labs would not be able to afford and thus the traditional technique of backflushing is still preferable which requires only often change out of inlet liners. Would you agree ?

Hi Peter!

You have a valid point. A lab’s cost per analysis can easily impact capital equipment investment. Of course this technique isn’t going to work for every single lab, but in my opinion it comes down to a few factors:

1.) How often GC consumables are being replaced.

2.) If the set-up is strictly used for dedicated analysis.

3.) If compound identification is important.

One example that comes to mind is a lab on an an offshore oil rig. Depending on the safety policies/requirements, an FID can be problematic to use, so VUV could be a viable alternative.