Published by Peter Boler on August 18, 2020

As COVID-19 continues to spread the toll it has taken on public health and global economies is hard to dispute. That combined with an oil price war between OPEC and Russia created a supply and demand imbalance. Demand decreased as travel restrictions and mandatory stay-at-home orders went into place while supply continued to increase resulting in significantly lower oil prices. While oil prices have recovered somewhat since early April the demand effects continue to linger.

As a result oil and gas companies have rightly acted to protect employees health and safety and by cutting or deferring discretionary capital and operating expenditures at all levels including laboratory operations. However, the crisis also presents an opportunity to reconsider how investing in newer technologies can improve operational efficiencies while simultaneously reducing long-term costs effectively positioning these companies to emerge from this crisis well positioned for the future.

One way to do this is for laboratory directors to use this opportunity to consider technologies and methods that allow them to consolidate tests that have traditionally required multiple analytical systems. This type of strategy can have a significant impact of laboratory cost and productivity because it effectively eliminates the need for multiple analytical systems, reduces the costs associated with maintenance and consumables and improves laboratory productivity and efficiency because analysts have fewer analytical technologies to learn.

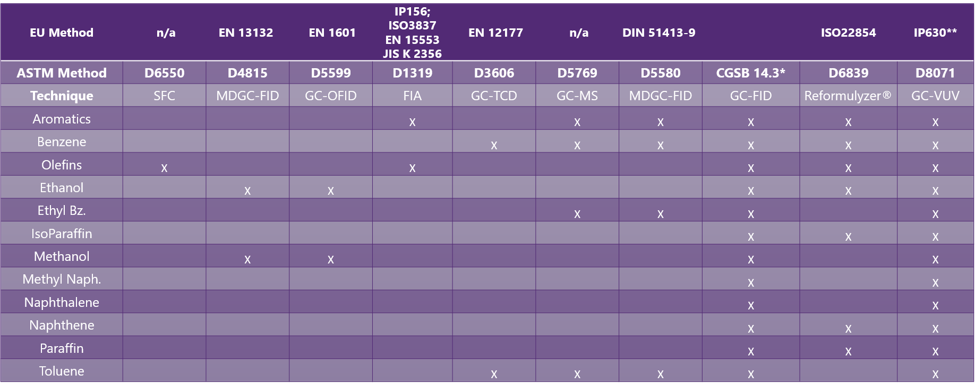

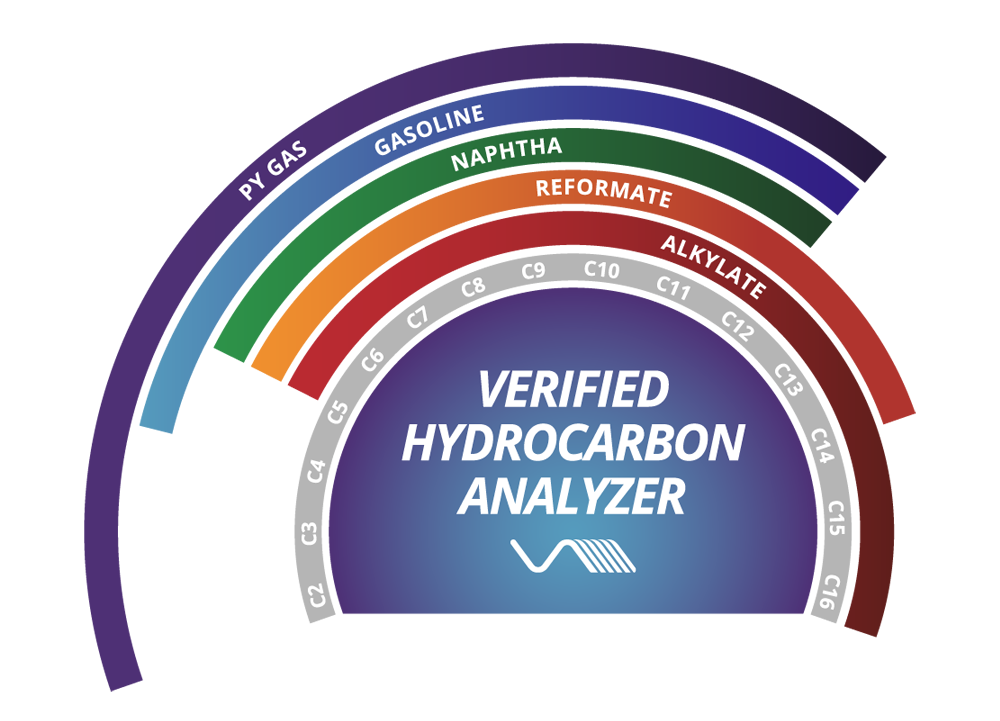

Consider the VUV Analyzer™ Platform for Fuels running ASTM D8071. This single platform can replace the need for multiple analytical techniques (Figure 1) including: ASTM D1319 using Fluorescence Indicator Absorption, ASTM D5599 using GC-OFID, ASTM D5769 using GC-MS, and ASTM D3606 using GC-TCD. Consolidating reduces costs and improves efficiency because it:

- Reduces the number of gas chromatographs from three to one.

- Reduces gas consumption because fewer GC are required.

- Eliminates the need for expensive maintenance on MS vacuum pumps and source optic cleanings,

- Eliminates the need for expensive maintenance on GC-OFID platinum reactors.

- Eliminates the needs for expensive dyes and time consuming analysis.

- Simplifies operation for the user through a single platform and automation.

- Frees up critical laboratory resources to work on other high priority tasks.

Figure 1

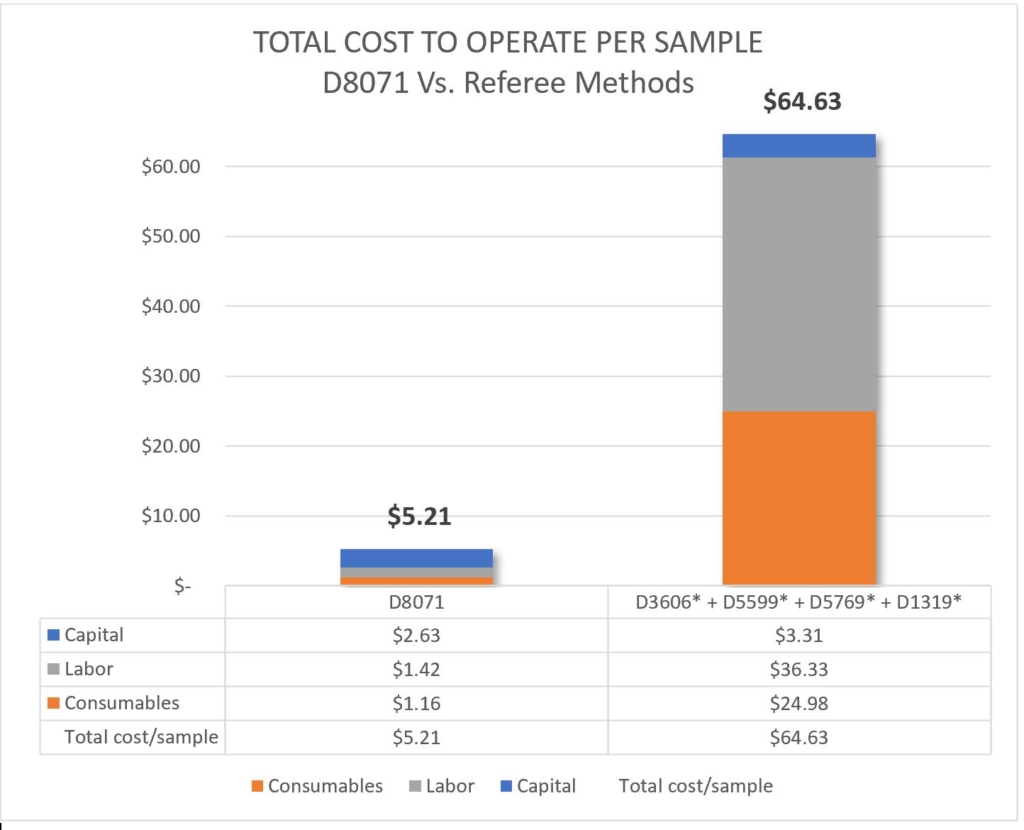

The cost savings associated with a consolidation strategy is best displayed in Figure 2. Operating the VUV Analyzer Platform for Fuels and ASTM D8071 is twelve (12) times less expensive to operate per sample compared to the sum of the other techniques. This dramatic difference is due in large part reduced labor costs associated with operating a single automated analytical platform and a dramatic reduction in maintenance and consumable costs.

Short-term responses to these crisis’s like cutting or deferring of capital operational expenditures have already been implemented. They should be continuously monitored and adjusted where needed.

However, laboratory leaders who want to emerge from the crisis positioned for the future need to start investing in the laboratory technologies that will allow them to reduce operating costs over the long-term while also improving efficiency and profitability.

In part 2 of the series we will dig a little deeper into the cost advantages of the VUV Analyzer Platform for Fuels by looking comparing different fuel types and method in more detail.

Figure 2

I am a bit worried about “productivity” or ” cost reduction ” emphasys at labs.

The main mission of labs is to give precise results for

clients to take decisions about actions to be taken.

Laboratories are part of an organization, not an isolated area.

Some times, to increase precision in results , some investments must be done, instead to reduce costs, in order to have global economy.

Hi Raul,

Thank you so much for your comments. You raise an interesting point about an over emphasis on productivity and cost reduction. I am certainly not arguing for cost reduction for the sake of cost reduction. Rather, I would argue that productivity, costs, and data accuracy are all related to each other.

More specifically, if you consider gasoline and the various methods highlighted in the blog FIA (ASTM D1319) is largely a manual method that is both time consuming and subject to human interpretation of results — which introduces the possibility of error. Also, it only provides results for aromatics and olefins – the latter of which is required for the EPA. For ethanol and methanol, you need to run the same sample by GC-OFID (ASTM D5599). GC_OFID is expensive to maintain due to the platinum reactors. Benzene is typically measured using GC-TCD (ASTM D3606). This is not a very complex approach but does require another analytical setup. Finally, aromatics is performed by GC-MS (ASTM D5769), which is more complex and maintenance intensive. These are four different analytical techniques which provide accurate results, but you still need to run all four which has an impact on cost and productivity.

My point is, that in times like this, most organizations are stopping or delaying investments which is understandable given the current economic climate due to COVID-19. However, sometimes it is better to invest, in times like these, in newer technologies and methods that provide (as you point out) accurate results while simultaneously reducing the number of analytical techniques used in the laboratory. This also reduces consumable and maintenance costs over the long term.

Additionally, by reducing the number of analytical techniques with a single technology and method that provides a more comprehensive set of results, you are simplifying laboratory workflow which has a direct impact on productivity, freeing up chemists to work on other more important tasks.

Thanks,

Pete

Hi,

I found information on the website quite interesting for a Scientist involved in a pharmaceutical/ Biotechnology industry. The detector is used for the detection of Nitrosodimethyl amine impurities and related compound with a specification of 26.5 to 96 ng/day.

I would like to suggest validate an analytical method and submit to FDA.

FDA may be published as an alternate method. You can also provide to your customer and they can validate and use it.

It will helps to sell this detector to industry as now a days more than 15 API are susceptible for these impurities.