Published Chris Cook on July 29, 2020

A rising baseline during your gas chromatography – vacuum ultraviolet spectroscopy (GC-VUV) runs can cause VUV Analyze™ Software to misidentify certain time slices as peaks when there is no analyte eluting and, in fact, the time slice should be identified as background. When this happens, VUV Analyze will take that peak area and add it to the “rejected” category because whatever was detected was not in the list of compounds it was looking for. If too many such time slices are rejected, it can take the run and analysis out of compliance with the ASTM D8071 (PIONA) and D8267 (jet fuel) methods. This post discusses the problem of rising baselines, some of the common causes, and ways to correct them to ensure you obtain accurate results.

Area Rejects Caused by Rising Baselines

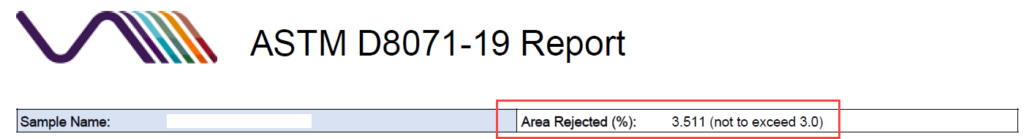

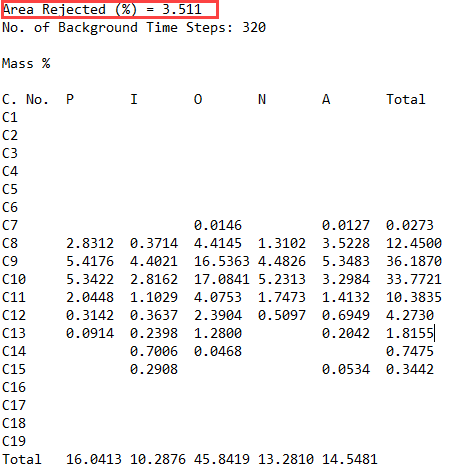

Often the first indication you will see of a baseline problem comes from a high area reject percentage. This value is shown at the top of the VUV Analyze PDF reports and above the mass% table in plain text reports, as shown in Figure 1A below. Time slices are rejected for not meeting the Chi2/R2 limits of the analysis parameters. As mentioned earlier, when VUV Analyze identifies a time slice as a peak but fails to find a fit, it will add the time slice to the area rejects. An area reject percentage greater than 3% in D8071 and D8267 analysis means that results of the analysis are invalid, as described by the ASTM methods.

Figure 1a

Figure 1B

Figure 1. Area rejects shown on D8071 reports. A) pdf report. B) Plain text report

Identifying a Rising Baseline

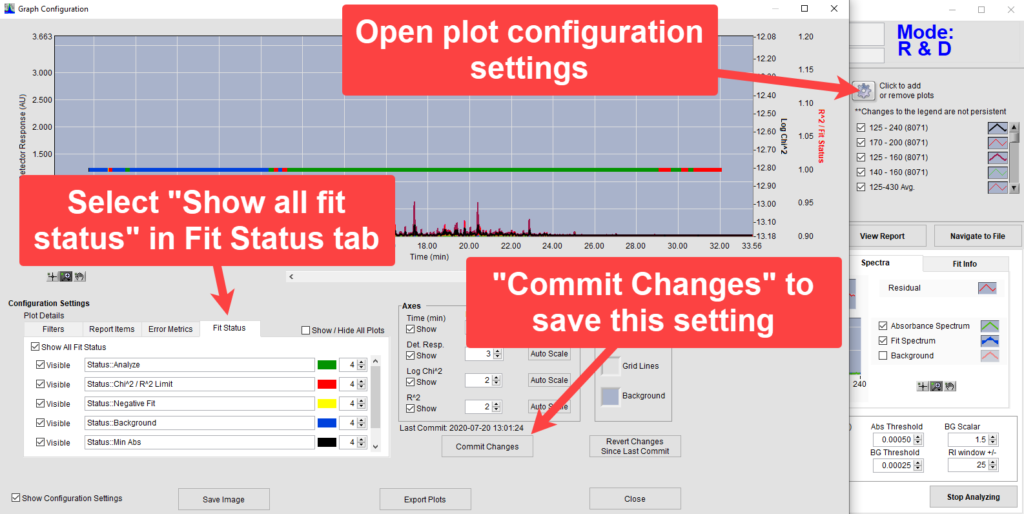

A high area reject percentage can be caused by several different things, including the presence of analytes in the sample that are not part of the library and times in the retention index file being off. Most commonly though the cause is a rising baseline. An easy way to check if a rising baseline is the cause of the high area reject percentage is to examine the fit statuses of the run in VUV Analyze. To view these, first go to R&D mode (accessed by Control+Shift+R), then click the gear icon to open the plot configuration settings.

Figure 2. Steps for showing Fit Status in VUV Analyze.

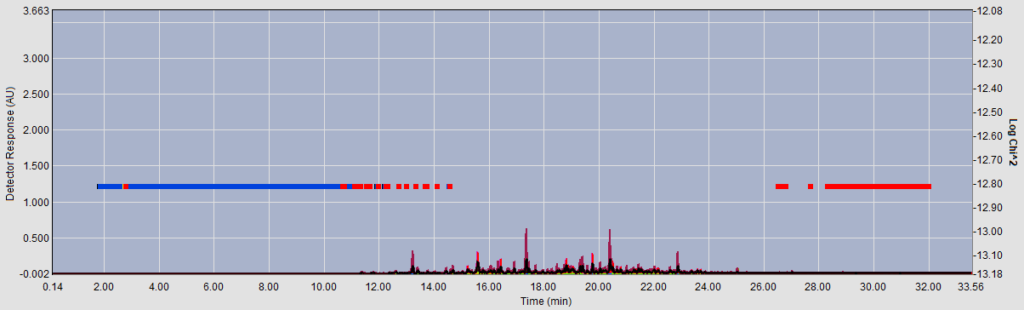

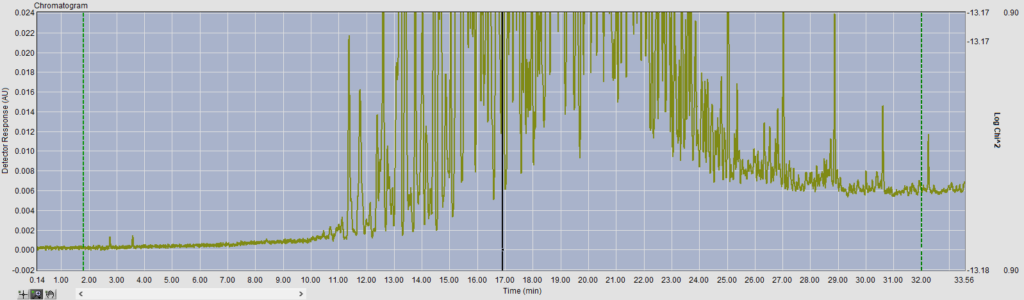

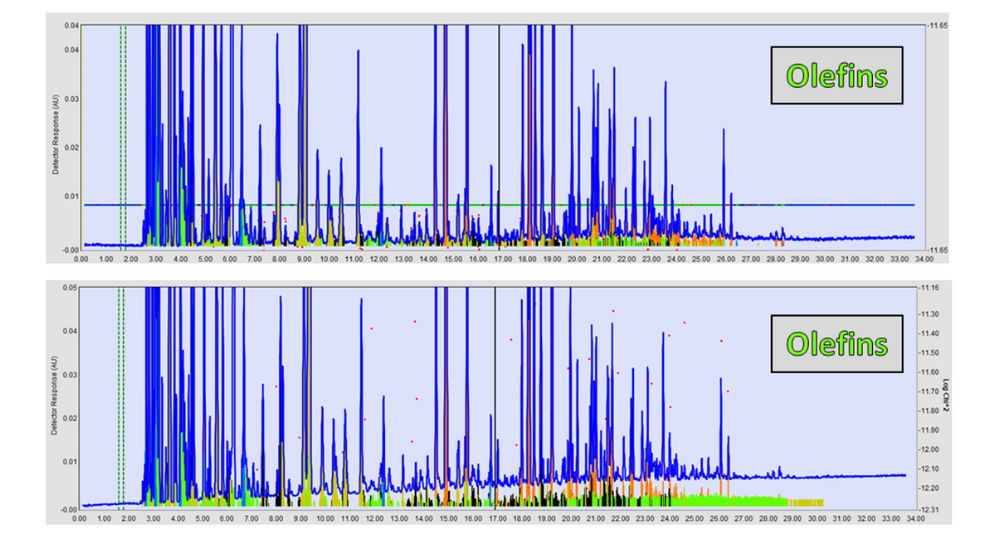

Unselecting the “Analyze” indicator (green) shows that most of the last several minutes of the run are marked with red, as in Figure 3. This indicates the fits in those time slices were rejected for not meeting the Chi2/R2 limits of the analysis parameters. This amount of rejected time slices at the end of a run suggests a baseline issue. Figure 4 shows the zoomed in view of the baseline and the rise in signal.

Figure 3. Chromatogram with large number of area reject time slices at the end.

Figure 4. Zoomed in view of same chromatogram showing rising baseline.

Examining the Rising Baseline in VUVision™ Software

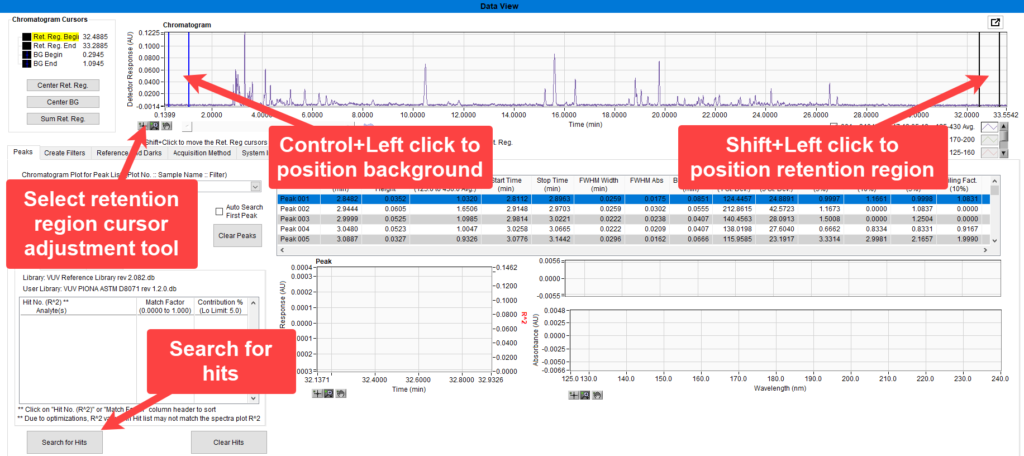

For further investigation of the issue, it is beneficial to examine the run file with VUVision Software. From the VUVision home screen, we go to the Data View window and open the run file in question. Positioning the background cursors at the beginning of the chromatogram and the retention region cursors at the end of the chromatogram shows the change in spectrum over the course of the run. Clicking “Search for Hits” shows library matches for the spectrum of the rising baseline (Figure 5).

Figure 5. Steps for examining the rising baseline of a chromatogram in VUVision.

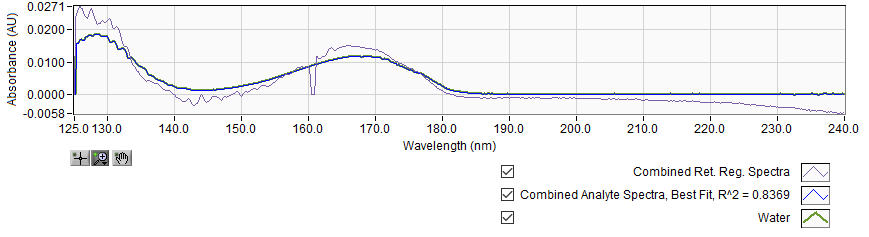

Water, Oxygen, and Miscellaneous Hydrocarbons

One common culprit causing a rising baseline is water, as seen in Figure 6. If water were present in the sample matrix of this D8071 run it would come out as a focused peak at around 2 minutes, but instead the water is constantly growing in the baseline of the run. When a GC is kept at room temperature for an extended period of time water can accumulate on the column. If the column is not cleared off before running a sample, the water can start coming out as the GC oven temperature ramps. The water will then show up in a large portion of the chromatogram, generally increasing with the GC oven temperature. Some ways to alleviate this problem include:

- Leave GC oven temperature at approximately 110ºC when not measuring samples.

- Run a blank sample like dichloromethane at the beginning of the sequence before measuring actual samples.

- Ramp the GC oven to 250°C for 5-10 minutes to clear off the column before running samples.

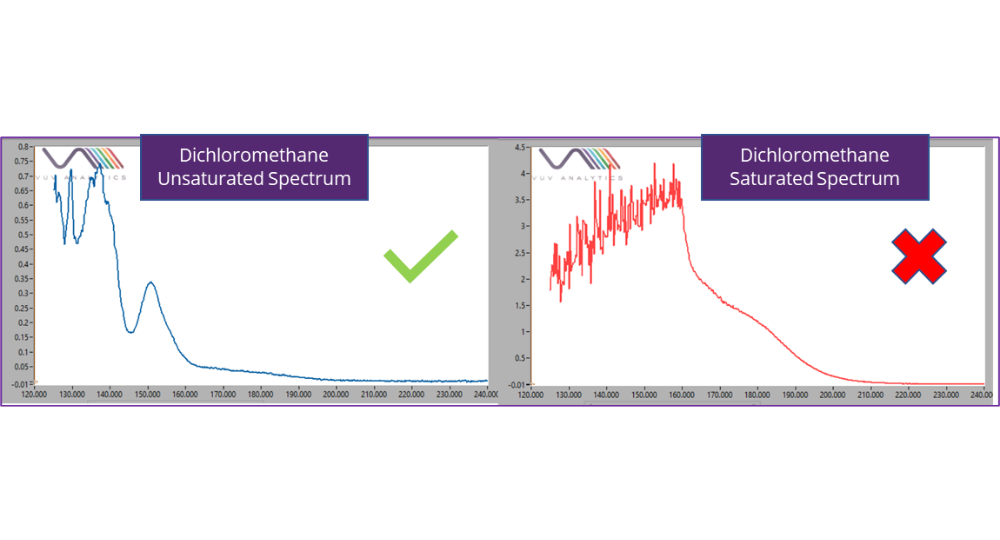

Figure 6. Water seen in the spectrum of a rising baseline. Downward spike at ~161nm is caused by a saturated lamp signal.

Another common issue is oxygen. The presence of oxygen indicates a leak is likely somewhere in the system. Possible corrective steps include:

- Changing the GC septum to prevent any atmosphere leak.

- Leak checking the connection of the GC column to the transfer line and tightening as needed.

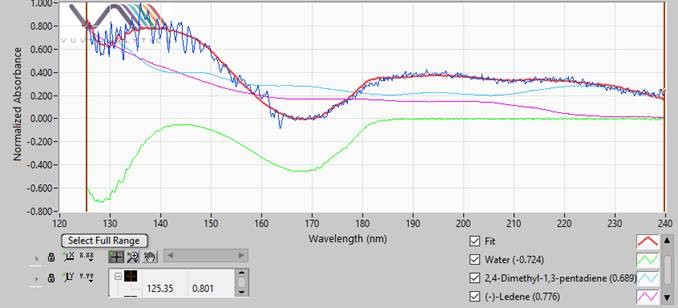

Sometimes if the GC has not been used for some time, troublemakers other than water can elute off the column and can cause a rise in baseline. Figure 7 shows an example of this, where a system was used for analysis after sitting idle for several months. We can see that there is some unknown hydrocarbon appearing in the baseline, with a negative water spectrum (green) that is caused by purging of the VUV instrument. If this is occurring, disconnect the GC column from the transfer line and bake the column off at 300˚C for 30 minutes.

Figure 7. Negative water on top of some other compounds.

Baseline Ringing and Temperature Variations

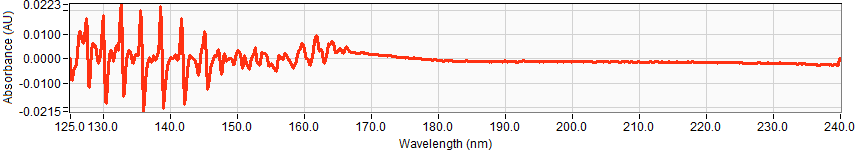

An effect sometimes seen in the baseline is the series of spikes shown in Figure 8, which we refer to as “ringing.” This is the result of subtle, non-linear changes in the spectrometer detector’s pixel sensitivity caused by temperature changes. Ringing is most common when nitrogen is used as a purge gas because of nitrogen’s sharp absorption features below 155 nm. When the detector is subjected to a change in ambient temperature, there are changes in the sensitivity of the pixels corresponding to the peaks and valleys of nitrogen’s absorption spectrum. This causes the absorption to appear artificially too high or too low, and the result is the ringing artifact. Fortunately, as long as the ringing is centered about zero it will not be analyzed as peaks in VUV Analyze and will not cause problems with rising baseline area rejects.

Figure 8. Ringing seen in a baseline spectrum.

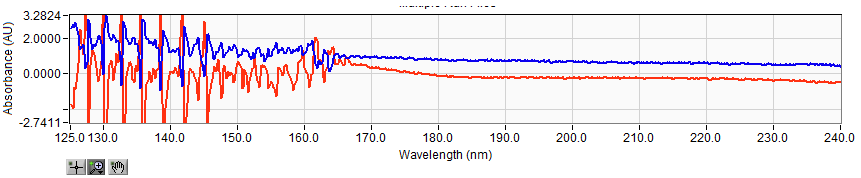

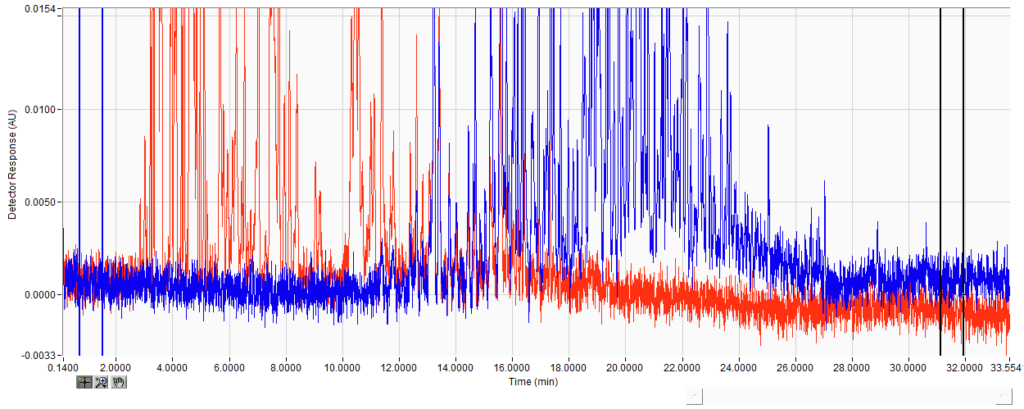

When there are changes of approximately 5˚C or greater though, detector response can be affected and lead to an overall rise across the entire spectrum. Figure 9 shows an example of an elevated response across the entire spectrum (in blue), and Figure 10 shows the chromatogram for this run. Some things to look at if you notice a rise in spectrum without much shape:

- Ensure no GC vents or cryogenic valves are blowing air on the instrument.

- Look for AC/heat outlets blowing directly onto the instrument.

- Check if the lab regularly changes temperature rapidly.

Figure 9. A run with an elevated baseline across the whole spectrum (blue) compared to run without baseline spectrum elevated (red). Both spectra show ringing, but the run with the red spectrum did not have a problem with baseline elevation area rejects because the spectrum was centered about zero.

Figure 10. Chromatograms for the two runs shown in Figure 9. Blue chromatogram showing elevated baseline, red chromatogram showing normal baseline.

In conclusion, a rising baseline is of particular concern when doing analysis with VUV Analyze Software applications because of the potential to cause a high area reject percentage. The causes of the rising baseline are often simple to identify and correct when you know where to look – and now you do!

Leave a Reply