Published by Chris Cook on April 30, 2021

In my previous blog, I discussed the standards used for setting up the ASTM D8071 PIONA analysis in VUV Analyze. In this installment, I’ll be talking about the chemical standards used for ASTM D8267 – the test method for the determination of total aromatic, monoaromatic, and diaromatic content in jet fuel. There are a few differences in how the setup works compared to our gasoline method, and this blog will review how the jet method standards should be used.

VUV-2

The chemical standard we call VUV-2 is the system validation mixture described in the ASTM D8267 Method. It’s a certified gravimetric standard manufactured to ISO17034 standards that contains linear alkanes from C6 to C21, as well as naphthalene, 2-methylnaphthalene, and 1,2,4-trimethylbenzene. While the D8071 PIONA analyses had a separate retention time standard (VUV-RT) and system validation mixture (VUV-1), the jet method setup uses VUV-2 for both these purposes.

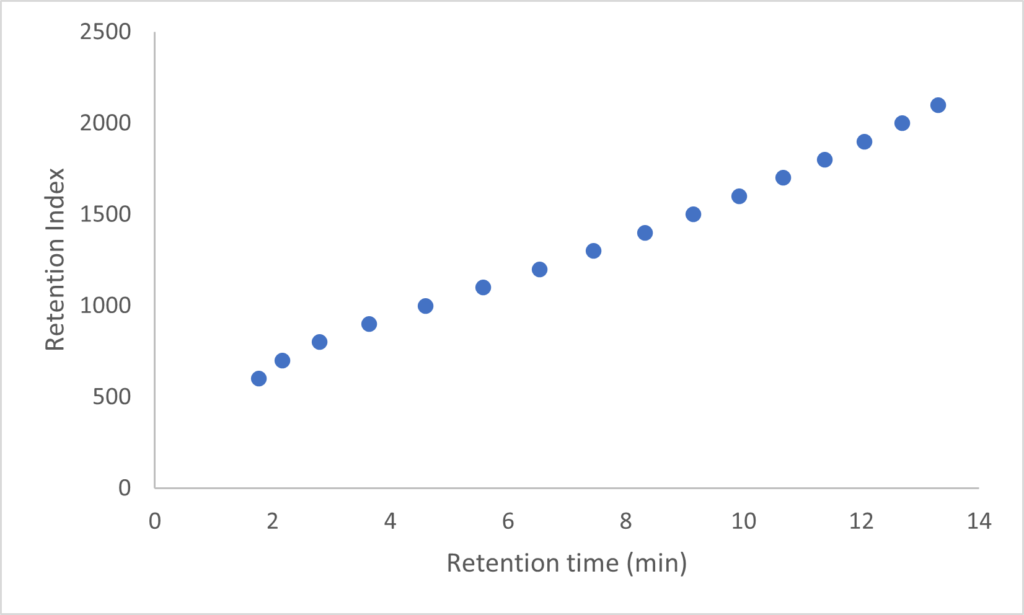

When VUV-2 is analyzed in Setup Mode, VUV Analyze will first create a retention index file from the linear alkanes.

Figure 1. A plot of VUV-2 retention times (min) and retention index values.

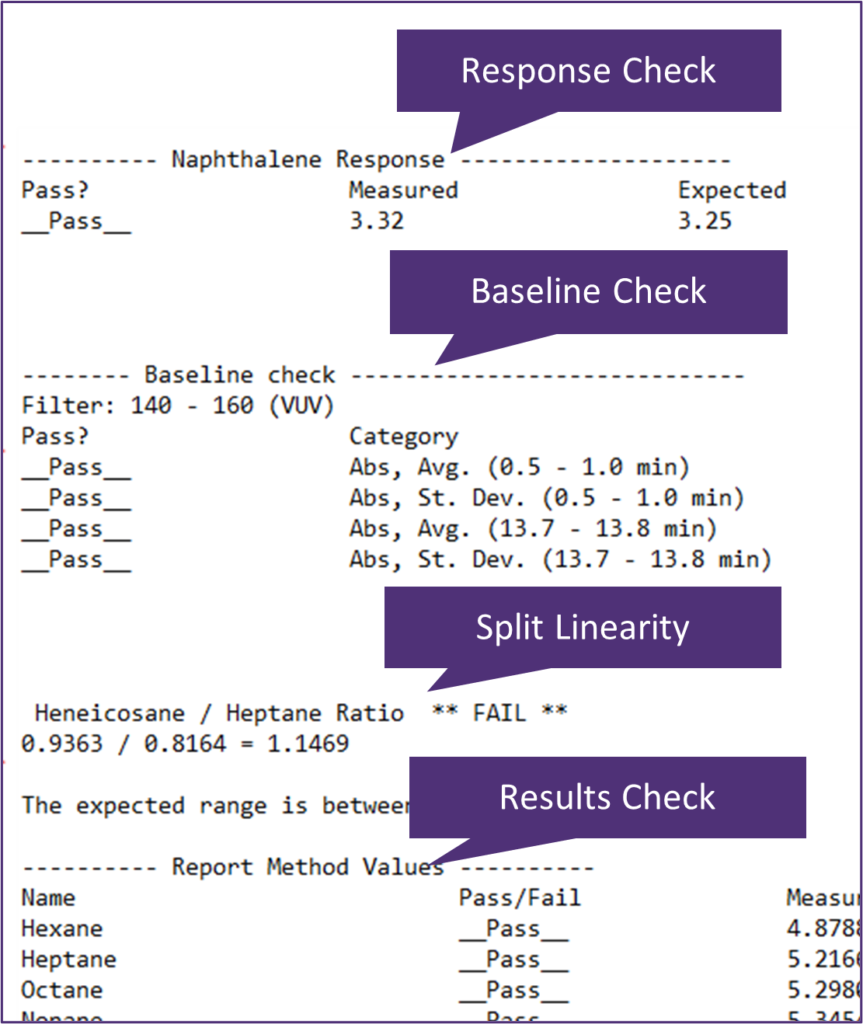

VUV Analyze will then perform several checks on the run using the retention index values it has just determined. The software will check the naphthalene response (just like how benzene is used in VUV-1) and will suggest a makeup gas pressure to use if the response is outside the specified range. The baseline is checked at the beginning and end of the run to ensure there is not excessive drift or noise in the baseline. The C21/C7 ratio is examined to assess split linearity. This check could fail if there is inlet mass discrimination, which will cause the check to fail high, or sample degradation, which could cause the check to fail low. Finally, VUV Analyze checks the percentages of all components of the mix to ensure that they are within +/-10% of the certified concentration values.

Figure 2. Excerpt of a VUV-2 report with the system checks having been run.

According to the ASTM method, VUV-2 should be run after significant maintenance of the GC-VUV setup or when the oven parameters are changed. VUV-2 may also need to be run if there are shifts in the retention times due to column aging and the production file needs to be updated.

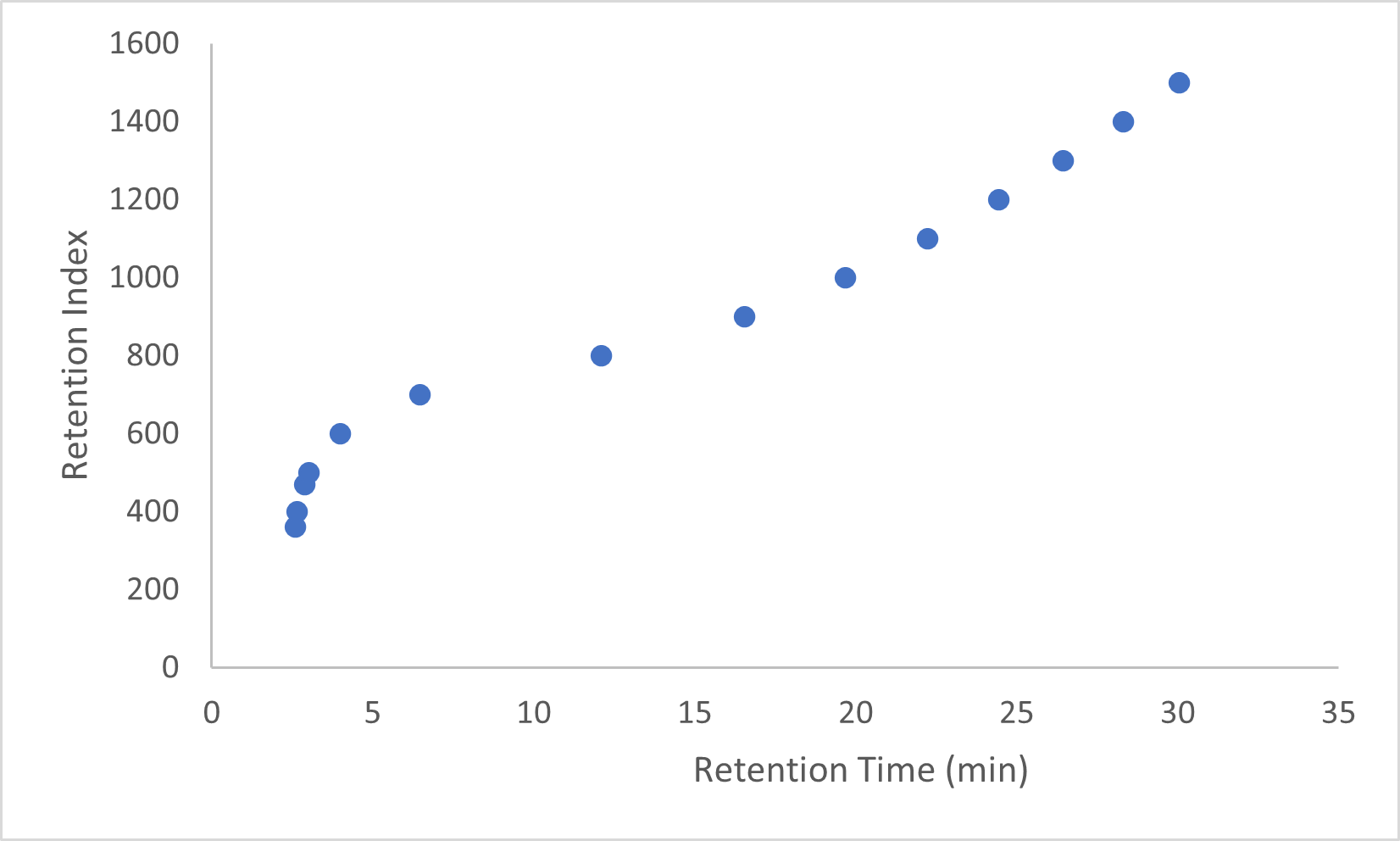

VUV-QCJ

The quality control standard we provide for ASTM D8267 is what we call VUV-QCJ. It’s a very well-characterized civil jet fuel that was included in the interlaboratory study for the method. During setup, VUV Analyze Software analyzes the VUV-QCJ chromatogram to check that the sample is in range for total saturates, total aromatics, and total diaromatics. According to the ASTM method, a quality control sample with similar characteristics to routinely analyzed samples should be run, and we make it easy for our customers by offering this well-characterized sample. Just like the check standard used for ASTM D8071, it should be run after every 20 samples.

Conclusion

The accuracy of our applications is something we’re very proud of here at VUV Analytics, and the proper usage of these chemical standards ensures you achieve and maintain that accuracy. Hopefully, you have a greater understanding of the purpose behind these standards and why they’re important. For more information about proper method setup or to order some more of these standards, please send us a support inquiry!

Leave a Reply