Published Dan Wispinski on July 13, 2020

In part three of this blog series (read Part 1 and 2 here) I will focus on the status of the Standard Test Method for Detailed Hydrocarbon Analysis by High Resolution Gas Chromatography with Vacuum Ultraviolet Absorption Spectroscopy (GC-VUV) in the ASTM process and its greatest applicability.

The draft ASTM method’s scope first mentions that it is applicable to “typical products encountered in petroleum refining or biofuel operations, such as blend stocks; naphthas, reformates, alkylates, FCC gasoline, liquefied petroleum gas (LPG)…” and then the scope states that “spark-ignition engine fuels….” can also be analyzed. Talking about refinery streams before spark-ignition engine fuels (ASTM’s term for gasoline) is no accident. I believe that the greatest advantage of Verified Hydrocarbon Analysis™ (VHA) is to refinery streams.

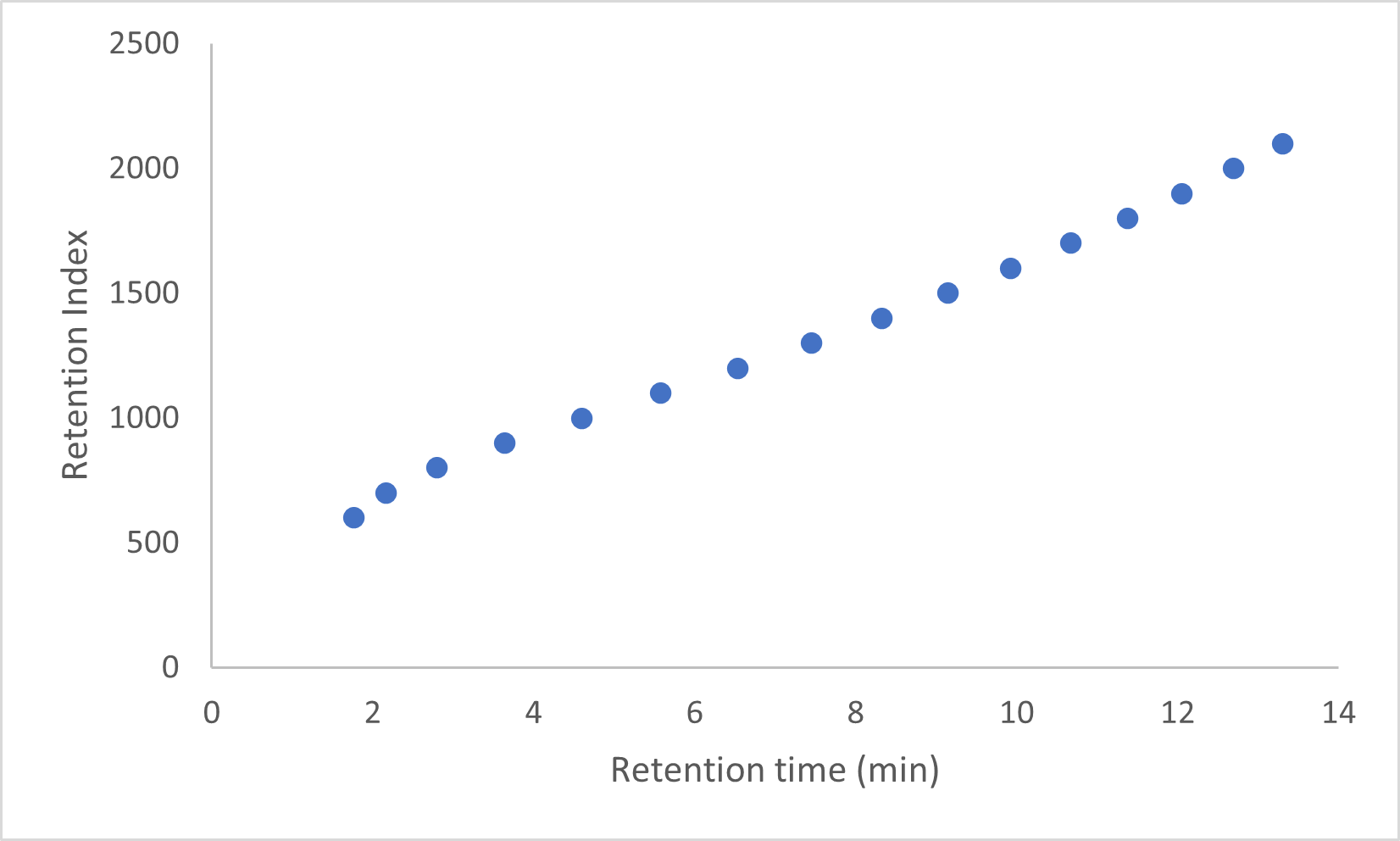

DHA by GC-FID is very common in refinery labs. The chemist is somewhat free to choose modifications to ASTM methods of D6729 and D6730. These deviations from ASTM may be to the carrier gas (e.g. hydrogen), oven temperature profile or to the column (e.g. high speed, high resolution microbore columns). A common method modification is the use of sample templates or reference chromatograms.

The use of these customized templates improves the accuracy and efficiency of the DHA analysis. The chemist chooses the right template for the right sample and then goes through the tedious process of properly integrating the chromatogram and matching all the sample peaks to the reference template peaks for the particular stream.

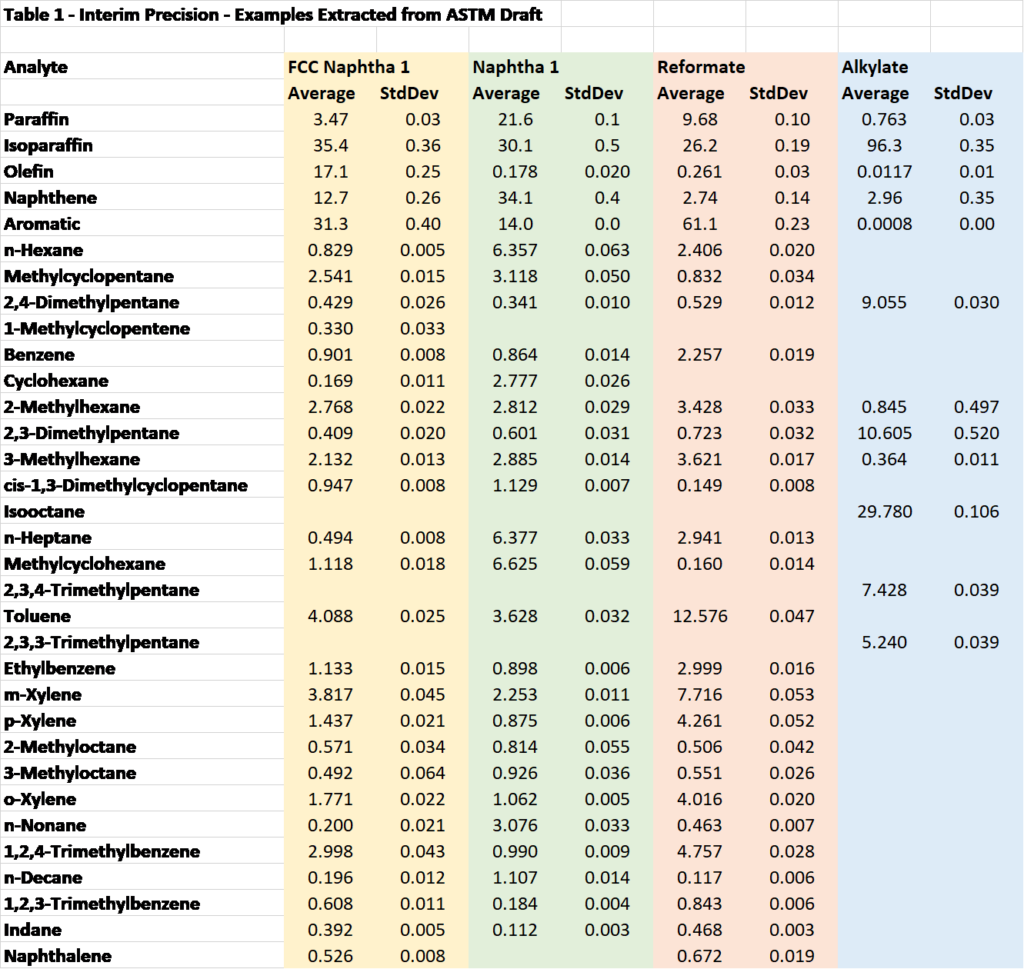

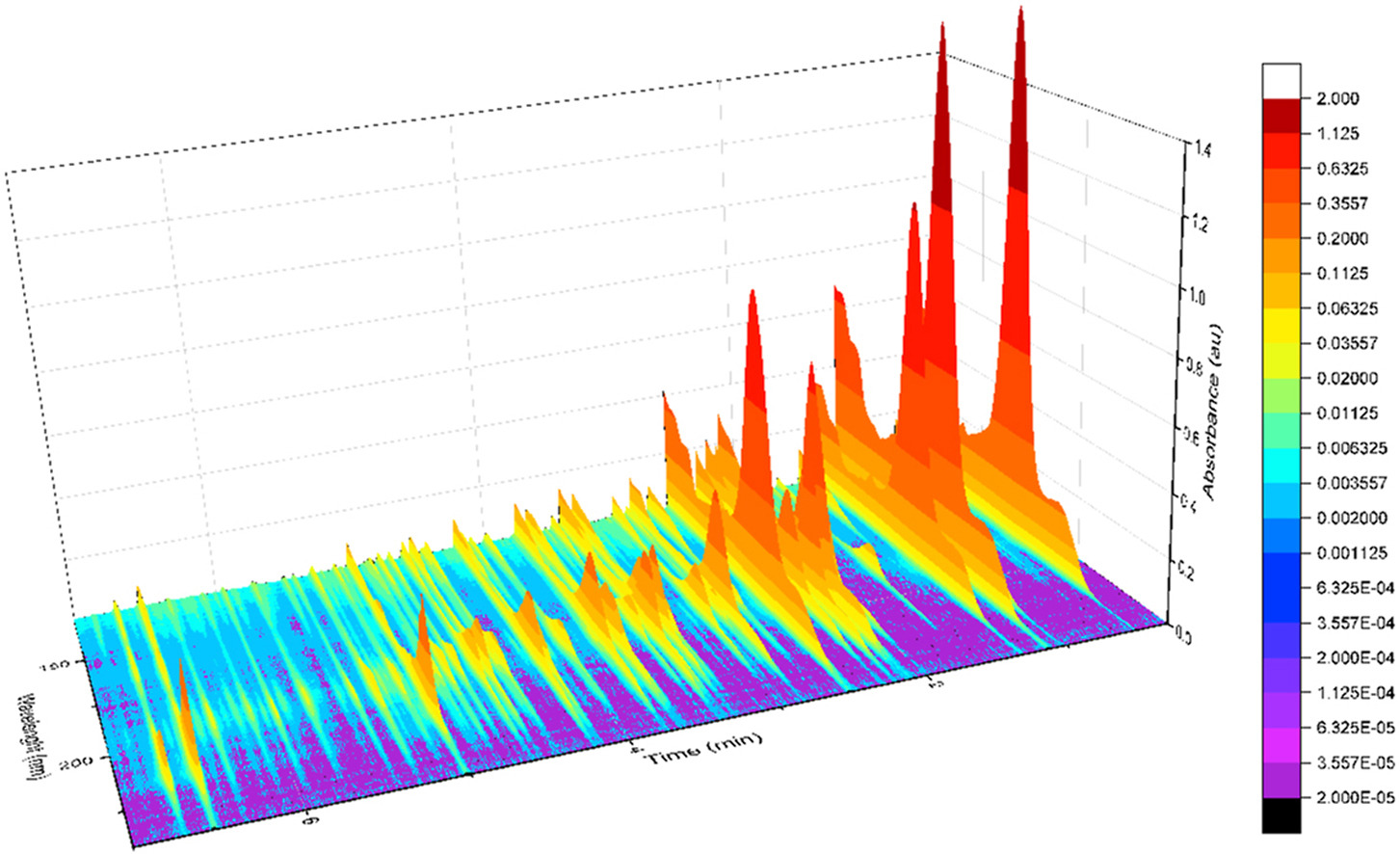

The VHA analyst would begin with the same process; choosing analytical parameters that are most suitable to their site and then also matching a template or spectral library specific to the refinery stream of interest. After, this is where VHA begins to shine and the advantages become clear. There is a significant GC run time savings of up to 90 minutes. The automated data analysis saves chemist time as well. This means that the refinery chemist can provide the engineering group much faster turnaround times and with more reliable data. VHA eliminates common DHA component mis-identifications, reduces unknowns to zero and provides better precision (Table 1 Interim Precision -Examples Extracted from ASTM Draft).

The bigger picture is refinery operation optimization. Refinery blending streams are of course components of the final product. Blend targets of these final products can be optimized using lower cost streams when there is confidence in data quality. Better precision of the components matters. The return on investment of VUV technology is quickly realized by taking advantage of blend stream price differences. ROI is also realized on refinery unit optimization. Reformer performance and the resulting octane number of the reformate is a function of the feed naphtha properties with higher naphthene and aromatic content being more desirable. Forward thinking refiners are already employing on-line VHA to match laboratory bench top VHA to optimize operations.

If refiners and laboratories routinely modify either DHA or VHA methods then why is an ASTM method important? The ASTM method provides legitimacy, defines product types and components that can be analyzed, concentration ranges of the components, provides starting analytical conditions, specifies necessary laboratory materials and equipment and indicates the expected precision of the analysis. The GC-VUV method is in the balloting process at the D02.04 subcommittee level. I expect the method to be published this year.

Leave a Reply