Published Chris Cook on March 5, 2021

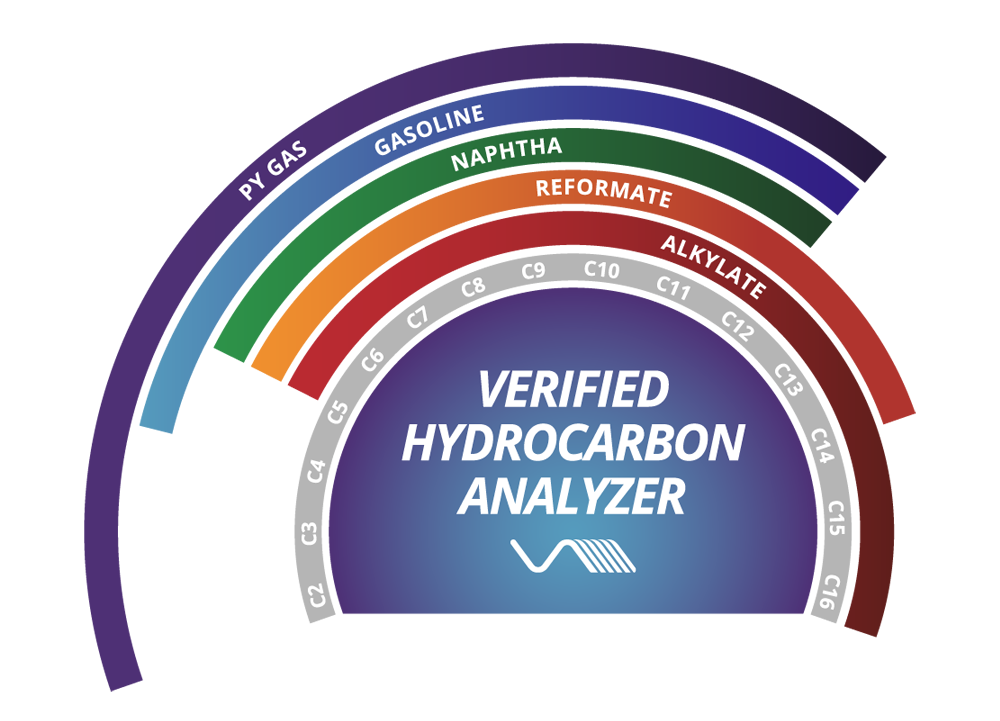

The gasoline analysis method for the VUV Analyzer for Fuels, ASTM D8071, is without a doubt our most popular offering. This is due in large part to the accuracy it provides compared to the alternatives. To maintain this accuracy, the method calls for the use of three separate standards to set up and validate. In this blog, I’ll discuss what those standards are, how often they should be run, and why they’re important.

VUV-RT

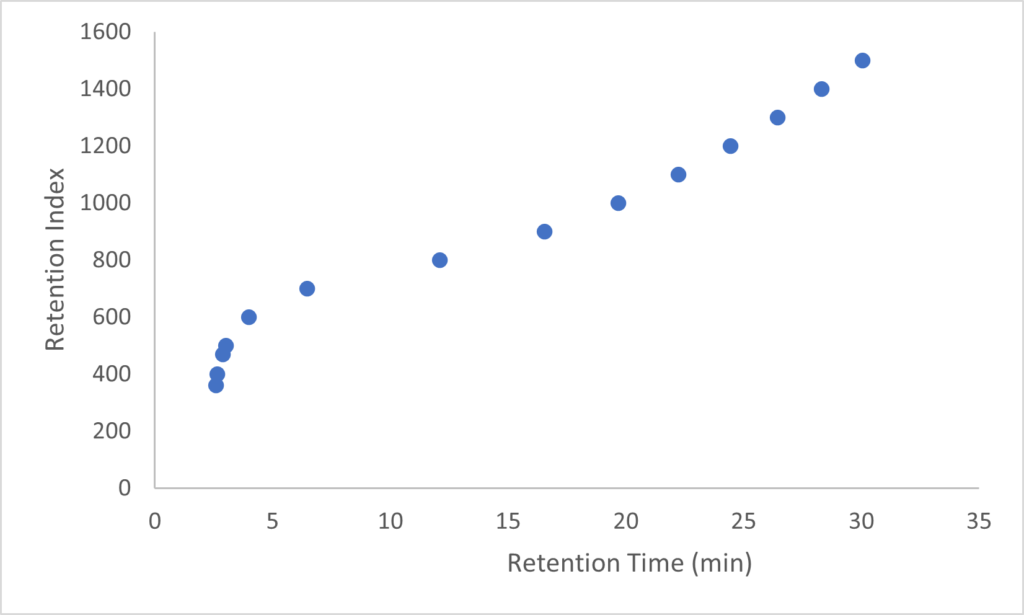

The VUV-RT standard consists of a mixture of linear alkanes in dichloromethane and is used as a retention time standard. VUV Analyze uses this standard to create a Retention Index file, which is a table of retention times and retention indices for the compounds in the VUV-RT standard. A plot of this data is shown in Figure 1. When performing a gasoline analysis, VUV Analyze uses this file to interpolate an average retention index for each time slice in the run file (see VUV 101: Time Interval Deconvolution).

Figure 1. Plot of VUV-RT retention times (min) and retention index values.

If analytes from the sample are not passing through the detector at the expected times (those predicted based on retention times and the RI file), there can be problems in the analysis (see Retention Time Issues in VUV Analyze Software Applications). If there are large shifts in retention times there may be problems with the GC itself, but minor shifts might be corrected by rerunning the VUV-RT standard. There is not a recommended interval for running VUV-RT, but it’s recommended to run it any time there are changes to the GC or VGA hardware. The best way to identify problems with retention times is to regularly run a QC standard. A visual way you can check the retention time repeatability when results start to drift is by overlaying the acquired chromatograms within the Data View window of VUVision.

VUV-1

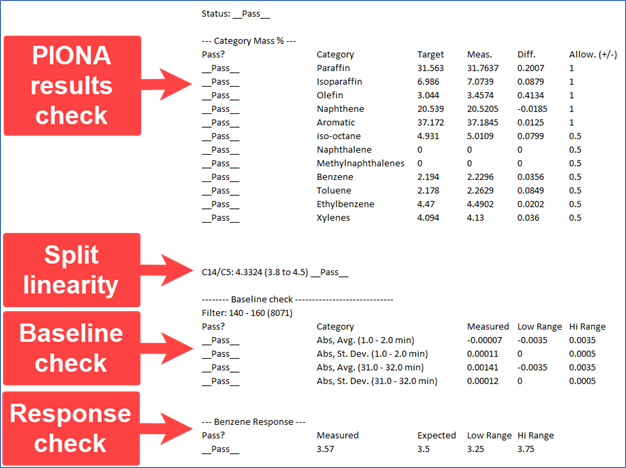

The standard we’ve dubbed “VUV-1” is a gravimetrically prepared solution that serves as the system validation standard described in ASTM D8071. VUV Analyze uses this standard to verify four things – detector response, baseline stability, split linearity, and overall analysis accuracy.

- Detector response – When VUV Analyze runs the ASTM D8071, the response calculated is the average absorbance in the 125 nm to 240 nm wavelength range. The response of the detector can be adjusted by changing the makeup gas pressure (see Dilution is Not Always the Solution: The Impact of Makeup Gas Pressure for a VUV Detector for GC). Greater makeup gas pressures means the sample has less time to absorb light in the flow cell and results in a lower response. During setup, VUV Analyze will check the benzene response and give a recommended makeup gas pressure if the response out of range. This step ensures uniform response across detectors and gas chromatograph systems, further standardizing the method and improving reproducibility. This check is shown in Figure 2.

- Baseline stability – To check the baseline stability of a VUV-1 run, VUV Analyze checks the average absorbance in the last minute of the run and compares that to the start of the run. The baseline absorbance in the last minute should change less than +/- 0.0035 AU. It cannot be overstated that baseline stability is critical to GC-VUV analysis. A drifting baseline can skew results and result in high area percent reject.

- Split Linearity – To test the split linearity, VUV Analyze checks the C14/C5 ratio from the VUV-1 run. A ratio that is not within tolerance may indicate a GC inlet leak, a temperature problem, or other issues. If the ratio is too high, it may mean that the standard has weathered, whereas if it’s too low, there may be mass discrimination in the inlet. It’s always best to use a new, properly handled standard to check split linearity.

- Analysis Accuracy – VUV Analyze also carries out a full PIONA analysis of the VUV-1 and checks the results for accuracy. The ASTM D8071 method specifies the tolerances, and if this test passes along with the others, you can be confident in proceeding.

Figure 2. Excerpt of a VUV-1 report with the system checks having been run.

There is no specified interval for running the VUV-1 standard, but like VUV-RT, it should be run and analyzed whenever hardware changes are made. A new ampoule should be used whenever VUV-1 is run to ensure that lighter components are not lost and the C14/C5 ratio check will pass.

VUV-CS

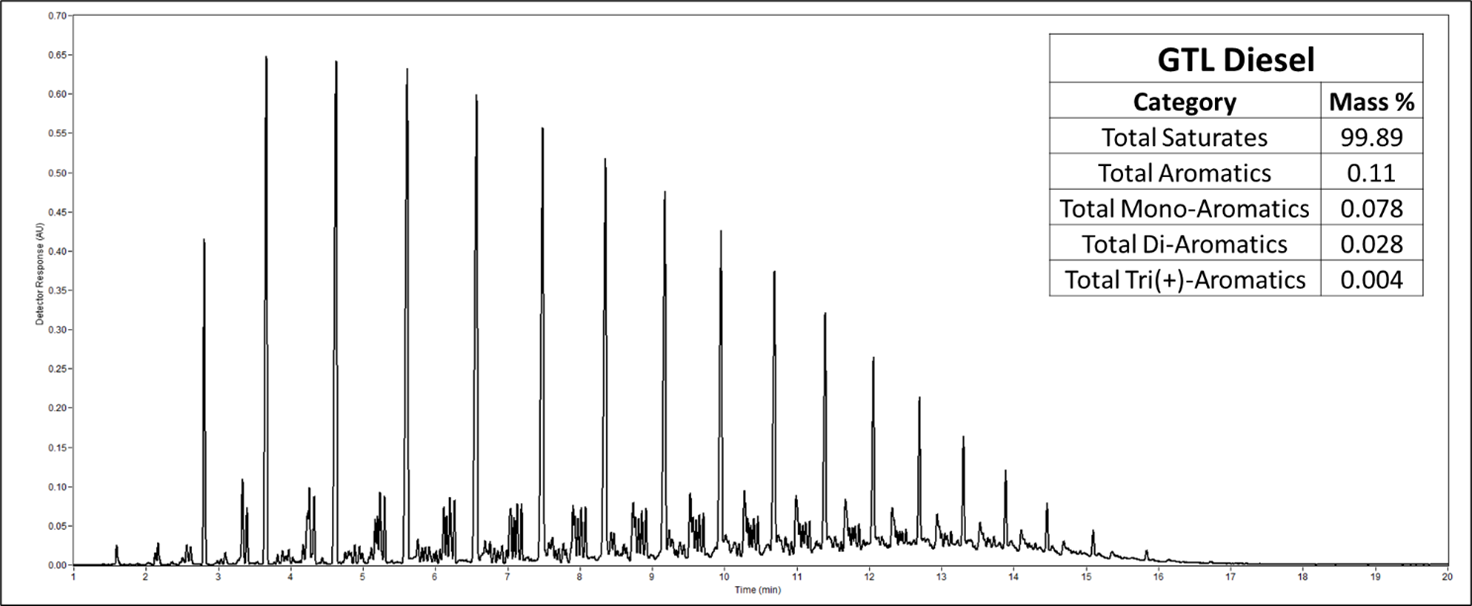

VUV-CS is an E10 gasoline sample that was included in the 2019 Interlaboratory Study for the D8071 method. When setting up the D8071 PIONA analyses within VUV Analyze, the software will check the VUV-CS results for paraffins, olefins, aromatics, ethanol, and benzene. These results are checked to verify that they are in the ranges established by the consensus results obtained from the D8071 Interlaboratory study. VUV-CS should be run at least as often as the VUV-RT and VUV-1 are run. VUV-CS can also be used for a quality control sample, in which case a good interval is one every batch of samples or after every 20 samples. VUV-CS meets EPA Accuracy Qualification Criteria and is manufactured under ISO 17034 accreditation.

Conclusion

Be aware that these standards are mandatory for compliance with the ASTM D8071 PIONA method because they ensure you obtain accurate results. Also, understanding what the standards are and how they work can help you troubleshoot issues. If you would like to learn more or ever need to order more of the standards, just drop us a line by sending us a support inquiry!

Leave a Reply